ABOUT

ALLIANCE

Alliance, the Total Solutions Provider

Alliance Construction Materials Limited (“Alliance”) is the leading concrete and aggregates total solutions provider in Hong Kong. Having grown hand in hand with Hong Kong since the early 1960s, Alliance has evolved as a joint venture since 2004, owned by CK Infrastructure Holdings Limited (“CKI”) and HeidelbergCement Group.

Embracing the international credentials and local expertise inherited from both CKI and HeidelbergCement Group, we provide innovative, reliable and customer-focused solutions on ready mixed concrete and aggregates to meet the most demanding requirements of construction projects in Hong Kong. For the past decades, we have been contributing to Hong Kong’s sustainable development. Our strong rock reserves and concrete production capability enable us to participate in major infrastructure, commercial and residential projects. Today, we have our own HOKLAS-accredited laboratory and Customer Service Centre to ensure product quality and customer satisfaction. We are committed to developing green products and services to build a better future.

As at 31 December 2018, we have 239 full-time employees and 180 contract drivers.

Embracing the international credentials and local expertise inherited from both CKI and HeidelbergCement Group, we provide innovative, reliable and customer-focused solutions on ready mixed concrete and aggregates to meet the most demanding requirements of construction projects in Hong Kong. For the past decades, we have been contributing to Hong Kong’s sustainable development. Our strong rock reserves and concrete production capability enable us to participate in major infrastructure, commercial and residential projects. Today, we have our own HOKLAS-accredited laboratory and Customer Service Centre to ensure product quality and customer satisfaction. We are committed to developing green products and services to build a better future.

As at 31 December 2018, we have 239 full-time employees and 180 contract drivers.

VISION

AIMS

PURPOSE

- OUR VISON

- To be no. 1 total solutions provider of concrete and aggregates in Hong Kong.

- OUR PURPOSE

- To build a great, livable city through sustainable concrete and aggregates solutions.

- OUR AIMS

- Our long-term success depends on strategies that can provide a good basis for sustainable development. Our key focus areas include building a trusting relationship with our stakeholders and to achieve operational excellence in a socially responsible manner.

- CUSTOMER FOCUS

- Build our success on our customers’ success with tailored solutions and all-round services.

- OPERATIONAL EXCELLENCE

- Improve the performance of all operations and functions and minimize our environmental impact.

- EMBRACE INNOVATION

- Develop innovative workflow, products and services to enhance our competitive edge.

- STAKEHOLDER ENGAGEMENT

- Enhance stakeholder relationships through two-way communication, support and continuous improvement.

MILESTONE

our journey since 1960s

1960s

Establishment of Pioneer Concrete (HK) and Ready Mixed Concrete (HK) Ltd. (RMC)

2004

Establishment of Alliance Construction Materials Ltd (Merger of Pioneer and RMC)

2007

- Development of the Integrated Management System (IMS)

- Obtained the ISO9001, ISO14001 & OHSAS18001 certificates

2008

Started Carbon Footprint calculation and set carbon reduction targets

2010

- Completed the Rehabilitation Works of Shek O Quarry

- Started to upgrade the trucks to EURO V

2011

- First to set up Customer Service Centre in the industry

- Obtained the 1st Concrete Product Carbon Footprint Mark from SGS

- Started our voluntary reporting on Sustainability

2013

- Started the ISO14064 GHG Verification

- Developed the Concrete Carbon Footprint Calculator to support customers’ low carbon purchase

2016

- Opening of STW Concrete Batching Plant, Phase 1 of Alliance’s Tsing Yi Concrete Hub

- Established the energy management system and obtained the ISO50001 Certification

2017

- Opening of TTS Concrete Batching Plant, Phase 2 of Alliance’s Tsing Yi Concrete Hub

- Completed the rehabilitation of Anderson Road Quarry

- Completed the replacement of mixer truck fleet to EURO V

2018

Detemined the “Alliance’s Sustainability Journey 2030”

OUR CAPABILITIES

Our Strategic Footholds

Our 6 concrete plants with 12 production lines are strategically located in various areas around Hong Kong Island, Kowloon and the New Territories, which can facilitate efficient concrete delivery throughout Hong Kong. Our aggregates supply are from 2 quarries in Guangdong Province in the PRC and we have 3 aggregates depots in Hong Kong. We maintain the largest mixer truck fleet with over 180 trucks which are configured with the largest capacity mixer drum in the market.

OUR PRODUCTION

- Annual concrete production capacity of 4 million m3

- Strong rock reserve of 70 million tonnes

- Strict environmental protection practices in all production facilities

OUR DELIVERY

- Strategically located plants to shorten delivery time and reduce carbon emission

- Environmental friendly Euro V mixer truck fleet

OUR MATERIALS

- All raw materials are from traceable sources to ensure good quality

- Regionally manufactured materials and rock products from green quarries

- Usage of recycled materials

OUR CONTRIBUTION

- Support the city’s development by infrastructure and other construction projects, creating usable land via quarry rehabilitation, as well as green products and services development

TESTING AND LABORATORY SERVICES

Through Concrete Services Limited, our HOKLAS-accredited laboratory, we provide a full range of professional services—including concrete mix design, lab testing and on-site testing.

- Strong support from HeidelbergCement headquartered in Germany

- Support customers’ projects from start to finish

- Offer innovative products with stringent quality control

ENABLE A

CIRCULAR ECONOMY

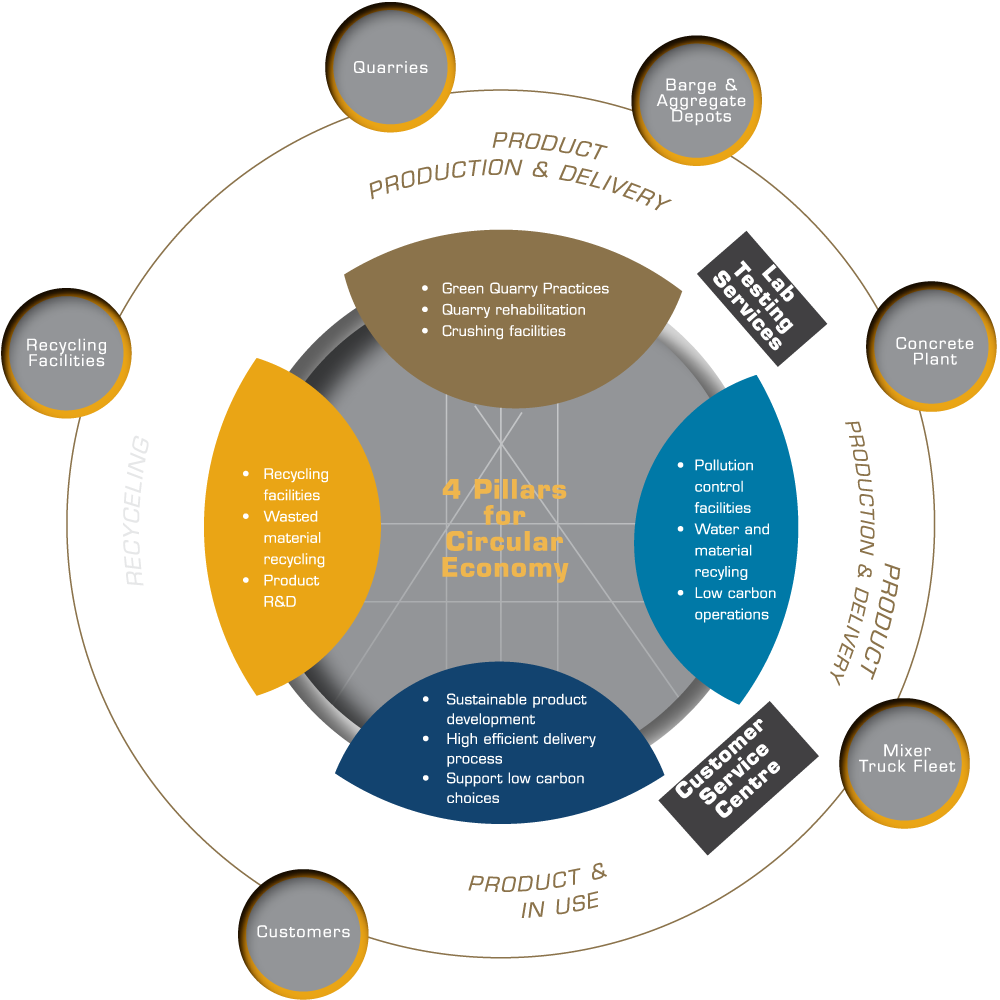

CIRCULAR ECONOMY

Our Move Toward The Circular Economy

Contributing to the Circular Economy is the drive behind our growth. By increasing our focus across reduction, reuse and recycling throughout all our production processes - from quarry product production to the concrete used in construction - the resources we use are increasingly finding ways for a useful end of life.